For electrical technology, Motor is known as the main unit of electrical technology. because of motor use in all industries with all machines and usually all the places normally. the Electrical motor is the main sub-sub-branch of electrical engineering because it is not easy to learn all concepts about electrical motor technology. There are many types and kinds of electrical motors like,

- AC motors

- DC motors

and there are also differents kinds in AC motors and DC motors as synchronous motors, induction motors, explosion proof, low voltage and motor with permanent magnet etc.

Where We Use AC Motors:

The alternating current electric motor (AC motors) are ideal for most applications linear, for fans, pumps, compressors, mills, machine tools, boilers, robots, generators and in many other products categories.As regarding the choice of the type of electric motor for a given application, this is influenced by different factors, starting from the costs of purchase and operation, the yield, the efficiency, the periodic maintenance.

Where We Use DC Motors:

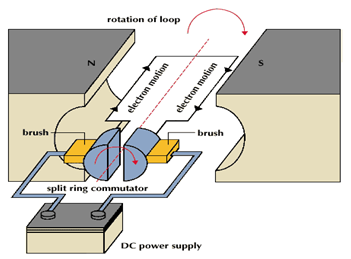

A DC motor is an electric motor that runs on direct current power. In any electric motor, the operation is dependent upon simple electromagnetism. A current carrying conductor generates a magnetic field, when this is then placed in an external magnetic field, it will encounter a force proportional to the current in the conductor and to the strength of the external magnetic field Resources and Information. is a device which converts electrical energy to mechanical energy. It works on the fact that a current carrying conductor placed in a magnetic field experiences a force which causes it to rotate with respect to its original position. Practical DC Motor consists of field windings to provide the magnetic flux and armature which acts as the conductor.

A DC motor is an electric motor that runs on direct current power. In any electric motor, the operation is dependent upon simple electromagnetism. A current carrying conductor generates a magnetic field, when this is then placed in an external magnetic field, it will encounter a force proportional to the current in the conductor and to the strength of the external magnetic field Resources and Information. is a device which converts electrical energy to mechanical energy. It works on the fact that a current carrying conductor placed in a magnetic field experiences a force which causes it to rotate with respect to its original position. Practical DC Motor consists of field windings to provide the magnetic flux and armature which acts as the conductor.Applications of DC Motors

Series Motors

The series DC motors are used where high starting torque is required, and variations in speed are possible. For example – the series motors are used in Traction system, Cranes, air compressors.

Shunt Motors

The shunt motors are used where constant speed is required and starting conditions are not severe. The various applications of DC shunt motor are in Lathe Machines, Centrifugal Pumps, Fans, Blowers, Conveyors, Lifts, Weaving Machine, Spinning machines, etc.

Compound Motors

The compound motors are used where higher starting torque and fairly constant speed is required. The examples of usage of compound motors are in Presses, Shears, Conveyors, Elevators, Rolling Mills, Heavy Planners, etc.